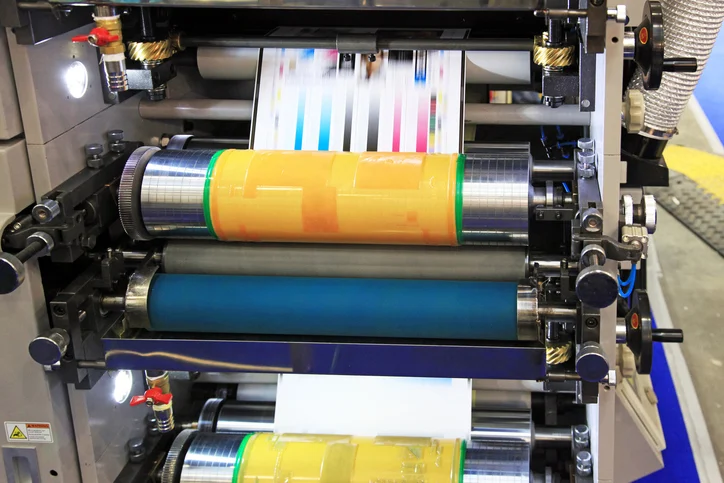

Narrow web printing plays a crucial role in industries such as packaging and labeling, where precision and color accuracy are key to creating high-quality products. At the heart of this process lies the choice of flexographic inks, which can make or break the final print results. As technology evolves, flexographic ink manufacturers are constantly innovating to enhance ink performance, durability, and environmental impact.

What is Flexographic Ink?

Flexographic ink is a fast-drying, versatile ink used in flexographic printing, a popular method for packaging and label production. Designed to work on a variety of materials like

- Paper

- Plastic

- Foil

These inks provide vibrant colors and sharp details. Flexographic inks come in different types, including water-based, solvent-based, and UV-curable, to suit diverse printing needs. Known for their efficiency and adaptability, they are essential for achieving high-quality and durable prints.

Understanding Narrow Web Printing

It is a specialized method used for printing on narrower materials, such as

- Labels

- Tags

- Flexible Packaging

As the name suggests, “narrow” refers to the width of the material, typically under 16 inches. This technique is widely used in industries where high-quality, detailed prints are essential, including food packaging, pharmaceuticals, and retail labels.

This process uses flexographic printing technology, which employs flexible rubber or plastic plates to transfer ink onto a variety of materials in a fast and efficient manner. It stands out for its speed, precision, and ability to deliver vibrant, sharp prints, making it the go-to solution for businesses that require consistent color, durability, and fine detail in their packaging and labeling projects.

The Role of Flexographic Ink Manufacturers in Quality Printing

Flexographic ink manufacturers are the driving force behind high-quality printing, creating innovative solutions that cater to the unique needs of various industries. They design inks that deliver vibrant colors, strong adhesion, and lasting durability on materials like paper, plastic, and foil, ensuring every print looks flawless.

With years of research and collaboration, these experts continuously refine their processes to meet the demands of narrow web printing. Using cutting-edge technologies like advanced pigment dispersion and efficient curing systems, they don’t just improve print quality—they also make the printing process faster and more reliable, keeping businesses ahead in a competitive market.

Factors Influencing Ink Quality in Narrow Web Printing

- Ensures smooth ink flow and sharp, detailed prints, maintaining consistent quality.

- Matches the fast-paced operations of narrow web presses to avoid smudging and ensure efficiency.

- Directly impacts color vibrancy and durability for vivid and long-lasting prints.

- Meticulous management of these factors helps printers achieve reliable, high-quality outcomes.

- Proper ink formulation reduces issues like clogging, streaking, and uneven coverage.

- Compatibility with various substrates ensures optimal adhesion and print performance.

- Resistance to wear, fading, or environmental factors enhances the durability of printed designs.

- Tailored ink properties support precise color matching for consistent branding.

- Advanced testing by manufacturers ensures the inks meet industry standards and client expectations.

How Flexographic Ink Manufacturer Improve Efficiency and Sustainability

Flexographic ink manufacturers are increasingly focused on enhancing both efficiency and sustainability in their products and processes. They achieve this in several ways:

1. Optimized Ink Formulations

Manufacturers create inks that work efficiently at high speeds, reducing waste and ensuring fast drying times. This allows printers to run longer production runs with fewer interruptions, improving overall efficiency.

2. Eco-Friendly Ink Options

Many manufacturers are developing low-VOC (volatile organic compounds) and water-based inks that reduce harmful emissions. These inks are safer for both the environment and workers, supporting a more sustainable printing process.

3. Energy-Efficient Curing Systems

Advanced curing technologies, such as LED or UV curing, consume less energy while maintaining high print quality. These systems help reduce the carbon footprint of the printing process.

4. Reduced Ink Waste

Manufacturers are refining ink formulations and application techniques to minimize ink waste during production. This not only makes the process more efficient but also contributes to cost savings and reduced environmental impact.

5. Sustainable Packaging

Many shifting to recyclable or biodegradable packaging for their products, further supporting sustainable practices in the printing industry.

6. Circular Economy Practices

By reusing and recycling ink waste materials, manufacturers contribute to a circular economy model that minimizes waste and optimizes resource use.

7. Long-Lasting Ink Durability

Sustainable ink formulations are not just eco-friendly—they are also designed to last longer. This means printed products, like labels and packaging, have a longer lifespan, reducing the need for frequent replacements.

Unlock Exceptional Print Quality with Vanguard Inks & Coatings

Choosing Vanguard Inks & Coatings in Forest City, NC, as your ideal partner for flexographic ink manufacturers is a smart decision for all your narrow web printing needs. Known for its commitment to quality and innovation, Vanguard offers a wide range of flexographic inks and coatings designed to meet the unique demands of the printing industry.

With their advanced formulations, they ensure exceptional print quality, vibrant colors, and strong adhesion on various substrates. Whether you’re looking for eco-friendly options or need reliable performance at high speeds, Vanguard’s tailored solutions help maximize efficiency and sustainability.

Partnering with Vanguard Inks & Coatings means gaining access to cutting-edge technology and expert support, making them a trusted ally in achieving outstanding results for your narrow web printing projects.