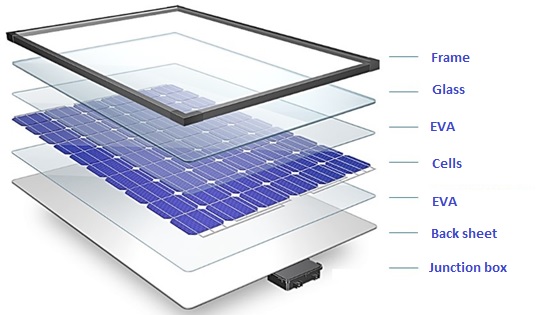

How thick should EVA Solar film be for module? this is our topic today. Here I’ll guide you, what exactly EVA Solar film is? please read the article til end. If you rad it carefully than only you can understand this product. The photovoltaic modules are made out of different parts that encompass the solar cells. Whose capability is to shield them from outside specialists. Such is the situation of the EVA encapsulant.

What is EVA?

EVA is ethylene vinyl acetic acid derivation, a material that has great radiation transmission and low degradability to daylight. This is a thermoplastic polymer, which is utilized in solar powered modules as an embodying specialist since, by applying intensity to the gathering, it frames a fixing and protecting film around the solar cells. It forestalls the passage of air and the arrangement of dampness, allows the sun’s energy to go through while being impervious to daylight debasement after some time.

Solar EVA Encapsulants

A solar module however looks straightforward, is a blend of profoundly designed materials cooperating pair to tackle energy. In this manner, every single part utilized influences its quality, toughness and is basically as significant as some other. One such part is the Ethylene Vinyl Acetate (EVA) encapsulant. This straightforward layer of plastomer structures a defensive layer over and under the solar cells forestalling water, soil and other outside pollutions from sullying the cells and simultaneously guarantees optical transmitivity and electrical seclusion. These encapsulants guarantee that the module can be involved outside for over 25 years absent a lot of corruption.

Product characteristics & specifications

- High light conveyance and low cloudiness rate during long time maturing process.

- Superb holding and grip to glass and back sheet.

- Superb enemy of yellow opposition for longer life.

- Great long haul warm properties like downer obstruction because of high crosslinking rate.

- Low shrinkage rate for further developed overlay security and lower dismissals.

- Long timeframe of realistic usability for better storability.

- High volume resistivity for lower PID impacts.

Standard thickness:

Creation size between 0.3 mm to 1.0 mm. Customary thickness: 0.45 mm ± 0.02 mm.

What occurs assuming the EVA is of low quality?

solar cells are made of silicon. This synthetic component will in general respond to different particles; among its top choices is oxygen. Assuming that the EVA is of low quality or the overlay cycle was not done accurately, the silicon wafer will come into contact with water or air (both exceptionally wealthy in oxygen) and the board will start to oxidize, looking yellow or brown contingent upon the case.

The outcomes? The board has lower proficiency, which will lessen the productivity of the whole framework.

How might you keep away from this?

Work with a sunlight powered charger provider that utilizes EVA brands with ensured quality, and with a severe Incoming Quality Control (IQC) cycle to test every unrefined substance got. That is the reason in ECO GREEN ENERGY we try to work with the best brands for every part of the boards and in any event, for the hardware of our production line.

EVA Resin Demand in Market

Assessed in view of 173 GW of yearly PV request in 2021 and the portion of encapsulant film determined by CPIA, there were 780,000 MT of EVA tar interest in 2021. Contrasting and 730,000 MT of EVA gum supply assessed by InfoLink, last year ought to see 50,000 MT of EVA lack. Vague POE maker let InfoLink know that genuine POE (polyolefin elastomers) molecule shipment surpassed 200,000 MT, 60,000 MT more than the graph shows. The additional POE molecule can compensate for EVA molecule deficiency.

EVA Film Ribbons Diamter?

With the reception of enormous organizations, current standard of the breadth of strips sits at 0.32/0.3mm, with EVA film weighing 480g and 460g on the front and posterior of a module. The heaviness of EVA film lessens as breadth of strips recoils. When SMBB comes into vogue, the heaviness of EVA film might diminish to underneath 400g/m2. In any case, estimation here is directed in light of 480g/m2 of weight, given vulnerabilities in ongoing turns of events.

EVA Film Global PV Demand?

In light of InfoLink’s most recent conjecture for worldwide PV request, there will be 930,000 MT of EVA sap interest and 160,000 MT of POE-based encapsulant request in 2022. Interest for EVA pitch will remain at around 890,000 MT, on the off chance that POE molecule supply supports at 200,000 MT.

Solar EvA Encapsulant Capacity

2021 saw a pinnacle of limit development in the encapsulant film area. Counting POE encapsulant, all out encapsulant limit could arrive at past 5 billion m2 toward the finish of 2022, supporting a larger number of than 500 GW of interest. Be that as it may, genuine advancement of new limits coming on the web is a lot of subject to late charging timetables and restricted EVA gum supply.

Hypothetically, there ought to be an apparent excess of encapsulant creation limit. Notwithstanding, the volume of successful limit is restricted, as likely to momentary natural substance supply bottlenecks and restricted genuine interest from the market.

According to development plans’ perspective, First Applied Material, HIUV New Materials, and Sveck hold the main 3 biggest producers. Cybrid Technologies, Lushan, and Betterial Film Technologies are likewise expectation on bigger extensions. For EVA film producers, the way to seriousness lies in guaranteeing their capacity to get materials in the midst of tight unrefined substance supply.

Read also: David Cassar Google PPC